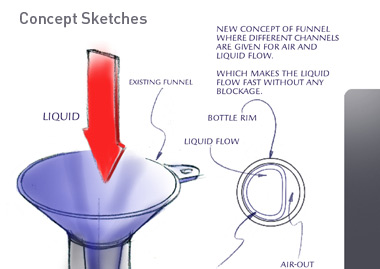

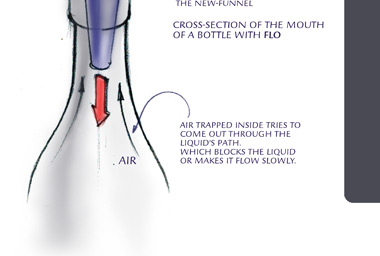

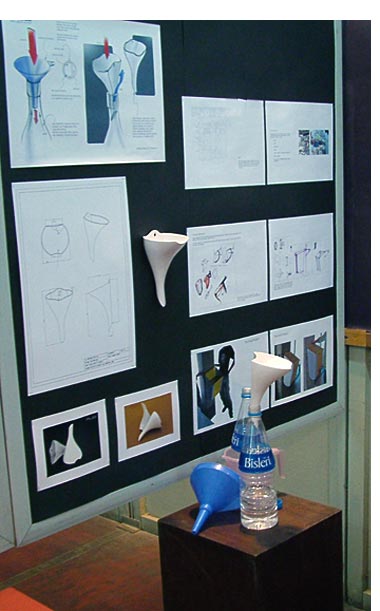

>> One common problem with existing funnels is when some liquid is poured in it, the liquid clogs up as the air inside the bottle can not come out and creates pressures in the opposite direction of the liquid flow.

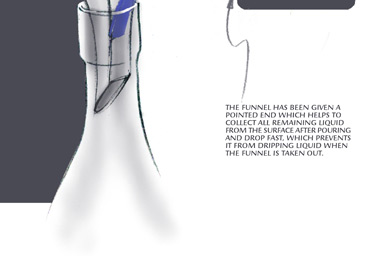

>> After pouring liquid using funnel the liquid stuck to the inner side of the funnel drips when the funnel is taken out from the bottle which makes it a messy job.

And I realized that there lies the root of the problem! As most of the bottles have round mouth the funnels tend to fit the mouth which blocks the air to come out.

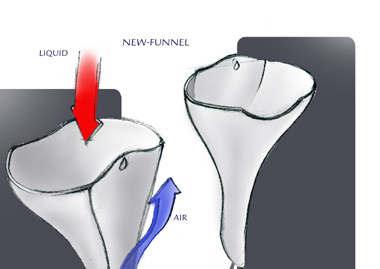

After trying for several solutions I found something which is perhaps the simplest possible solution, that is, make the funnel in such a way that it does not fit to the mouth of any bottle! As most bottles are with round mouth, it should have any shape other than full circular cross section which won’t fit to the circular mouth of the bottles/containers. After reaching this solution all other previous solutions started looking really silly!

My approach to the form was to make it different from the existing funnels exploiting the capabilities possibilities of modern injection molding of organic form.

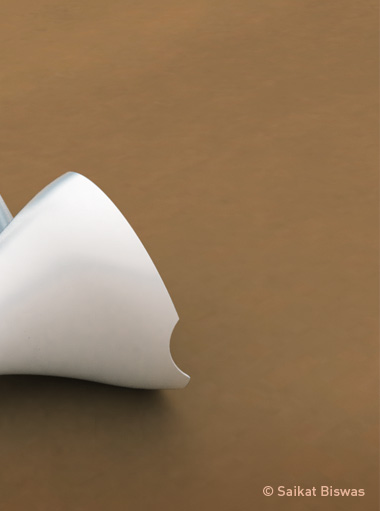

The form is organic and free flowing keeping one side almost flat which helps to form the channel for air outlet and at the round mouth of bottle as well as gives a vertical orientation while hung.

The end is chopped off at an angle which gives a sharp end to the form which helps the liquid to accumulate quickly thus dripping outside the container is prevented.